Electronic waste is now one of the world’s fastest-growing environmental challenges, with 62 million tonnes of e-waste generated last year and less than 20% being recycled. Within that, printed electronics recycling rates are less than 1%, highlighting a critical gap in the global transition to circular manufacturing.

Ail Arian, founded in Swansea, South Wales in 2024, is tackling this challenge head-on. The company has developed a patented, recyclable silver ink for use in printed electronics, a breakthrough that allows high-performance circuits to be recovered, reused, and reintegrated into the manufacturing cycle.

Turning Waste into Value

Printed electronics power everything from wearable technology to medical sensors and smart packaging. Yet, many materials behind these innovations are single-use, contributing to growing environmental waste and tightening regulatory scrutiny.

Traditional conductive inks present a double challenge. Not only is the silver within them difficult to recover, but contaminate the substrates, rendering the entire component non-recyclable. This contamination means valuable materials, plastics, films, and papers are lost to landfill or incineration rather than reintroduced into the supply chain.

This is where our product is different – How Ail Arian’s Recyclable Silver Ink Reduces Waste Contamination in Electronics

“Our mission is simple,” says Dr James Claypole, CEO and founder of Ail Arian. “We’re proving that sustainability and commercial success can coexist. Every gram of silver that’s reused is a win for both industry and the planet.”

Our Technology: A New Standard in Sustainable Conductive Materials

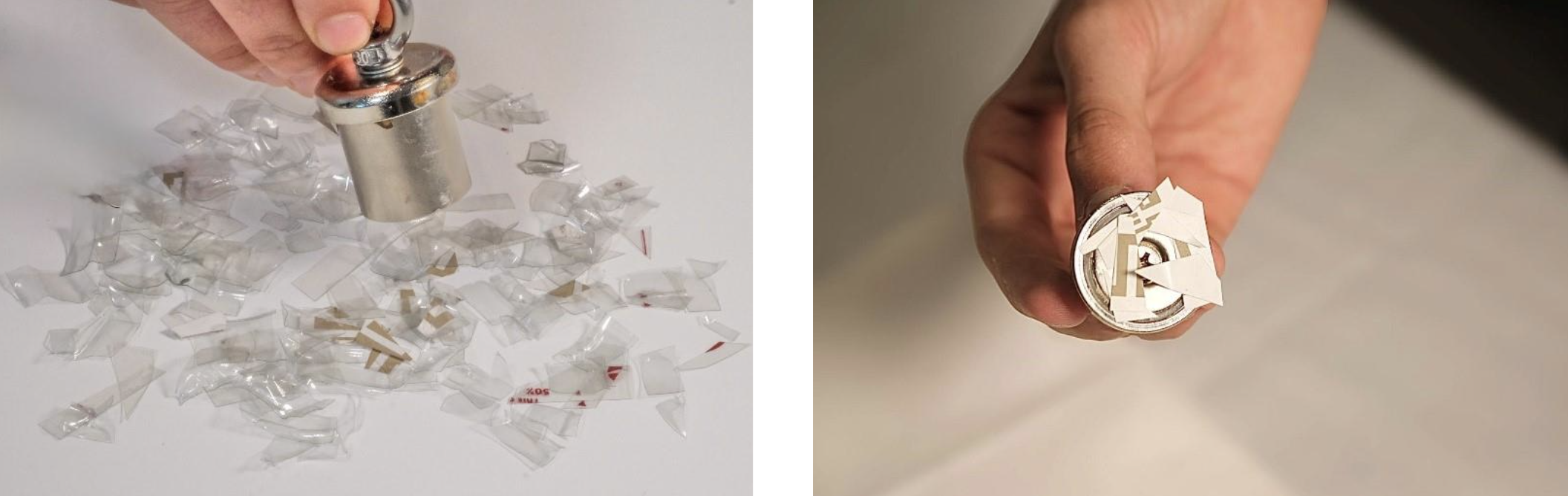

Ail Arian’s patented ink is manufactured using a specially modified silver material that has been engineered to be both conductive and magnetic. This enhanced silver is blended with selected polymers and solvents to create an application-specific conductive ink for printed electronics.

Crucially, the ink can be used by manufacturers as a direct, drop-in replacement for existing silver inks, requiring no changes to current printing processes or equipment.

By making the silver magnetic at the very first stage of production, Ail Arian enables the efficient recovery of silver and printed circuits using magnetic separation from the waste stream. This innovation unlocks a truly sustainable, closed-loop solution for printed electronics, reducing waste, conserving resources, and setting a new benchmark for circular manufacturing.

To watch our recycling process: Ail Arian Conductive Silver Ink Recycling Process

Why Manufacturers Will Need to Change

Global legislation is rapidly evolving to make sustainability a requirement, not a choice. Across the UK and EU, new rules on eco-design, digital product passports (DPPs), extended producer responsibility (EPR), and electronic waste recovery are holding manufacturers accountable for the full lifecycle of their products.

The introduction of Digital Product Passports, a key part of the EU’s Eco-design for Sustainable Products Regulation (ESPR) will soon require every electronic product sold in Europe to include a traceable digital record detailing its materials, recyclability, and environmental impact.

For producers of printed electronics, this means that adopting recyclable and recoverable materials is no longer optional, it’s essential for compliance, competitiveness, and future resilience.

“Ail Arian’s technology positions manufacturers ahead of the curve,” explains Hannah Claypole, Chief Marketing Officer. “Our recyclable silver ink not only meets the coming standards but helps companies future-proof their operations in a market where sustainability will define success.”

Regulatory Landscape Snapshot

- WEEE Directive (2012/19/EU) – Requires producers of electronic equipment to finance and organise end-of-life collection, treatment, and recycling.

- Ecodesign for Sustainable Products Regulation (ESPR) – Expands eco-design rules to include durability, repairability, and recyclability, and introduces Digital Product Passports (DPPs) to track product materials and environmental data.

- Digital Product Passports (DPPs) – Expected to become mandatory for electronics and batteries by 2027, giving every product a digital identity linked to sustainability and circularity data.

- Restriction of Hazardous Substances (RoHS) Directive (2011/65/EU) – Limits hazardous materials, making recycling safer and more efficient.

- UK Ecodesign Regulations – Promote energy and material efficiency for goods sold in the UK, aligning with EU sustainability goals.

- Extended Producer Responsibility (EPR) – Expanding frameworks that make manufacturers responsible for the full lifecycle of their products.

Together, these frameworks are driving a new industrial standard, one where circularity, transparency, and material recovery are fundamental to business success.

A Growing Market with Circular Potential

The global conductive ink market is valued at around $3 billion USD, with silver-based inks accounting for approximately 60% and representing a $1.7 billion early-adopter market for recyclable alternatives.

As demand for flexible and sustainable electronics accelerates, Ail Arian’s patented recyclable ink is positioned at the forefront of this transition, offering manufacturers a route to circularity without compromising performance or scalability.

Recognised for Innovation and Impact

Ail Arian’s leadership in sustainable materials has already earned major recognition. The company received an Innovate UK Start-Up Grant of £250,000 and a Welsh Government SMART FIS Grant of £200,000 to advance its R&D and scale-up plans.

It was also named Welsh Winner of the Manufacturing & Engineering Start-Up of the Year Awards, and is a finalist in the LOPEC Start-Up Awards, the UK Start-Up Awards, and a nominee for Innovation Entrepreneur of the Year at the Allica Bank Entrepreneur Awards next month.

Educating the Next Generation

Beyond innovation, Ail Arian is deeply committed to community impact. Through its school’s outreach programme, the company educates young people across Wales about recycling, electronic waste, and sustainable engineering, inspiring the next generation of innovators. The session includes a hands-on experiment which allows the children to transform a printed circuit into planted wildflowers, with the silver ink being recovered and reused.

“Our outreach work is about showing students that science and sustainability can go hand in hand,” adds Hannah “We want to empower young minds to see how responsible design can shape the future.”

Scaling for Growth

Ail Arian is now seeking investment to scale production and accelerate market entry. With rising interest from UK and European manufacturers, the company is poised to lead the shift toward sustainable materials in a printed electronics market projected to exceed £50 billion globally by 2030.

To support this next phase, Ail Arian offers SEIS tax relief to qualifying investors, providing attractive incentives for those looking to participate in the early stages of a high-growth, impact-driven business.

“With circularity at the heart of our business model, we’re aligning environmental responsibility with economic opportunity,” says Dr Claypole. “Ail Arian’s recyclable silver ink isn’t just a product, it’s a pathway to a more sustainable, profitable future for manufacturing.”

A Vision for Circular Electronics

As Ail Arian grows, its mission remains clear: To make every circuit recyclable, and every innovation responsible.

For investors, Ail Arian offers the opportunity to help shape the future of sustainable manufacturing, where technology, regulation, and profitability move forward together.