Sovereign Metals updated its Mineral Resource Estimate (MRE) for Kasiya on Tuesday, where it confirmed Kasiya as a Tier 1 natural rutile deposit. The company also confirmed the mine’s potential to be a substantial source of low-CO2 footprint critical minerals natural rutile and graphite.

Kasiya is currently the world’s largest rutile deposit, with more than double the contained rutile of its closest rutile peer, Sierra Rutile, according to the latest MRE. Kasiya is also the world’s second-largest flake graphite deposit, according to the graphite by-product MRE.

Rutile mineralisation can be found in laterally extensive, near-surface, flat “blanket” form bodies in places where the weathering profile has not been substantially degraded. The MRE features extensive zones of exceptionally high-grade rutile that run simultaneously over an area of more than 180km2.

Overall, the new MRE reveals several additional substantial, but generally separate high-grade rutile zones, especially in the resource area’s southern and eastern regions. The discovery and identification of these new high-grade mineralised zones have been the driving force behind the resource base’s tripling.

Kasiya’s Latest MRE Findings

A total of 662M tonnes which is 37% of the total MRE, reports to the Indicated category, with a recovered grade of 1.73% RutEq at 1.05% rutile and 1.43% TGC.

The deposit is large, with high-grade rutile mineralisation grading 1.2%-2.0% in the first 3-5m from the surface. Mineralisation of moderate grade Rutile, which ranges in grade from 0.5%-1.2%, frequently continues from 5m to the end of the hole, where it remains open at depths of >10m in several drill-defined, N to NE-striking zones.

In the first 3-5m, graphite is generally depleted, with grades ranging from 0.1%-0.5% total graphitic carbon (TGC). Graphite grades normally grow with depth until about 8m, at which point they remain constant, ranging from 1%-8% TGC.

At depths of >8m, some of these zones contain graphite grades in the 4%-8% TGC range, indicating large coarse flake graphite volumes. So far the contained flake graphite by-product stands at 2.3b tonnes.

At depth, several higher-grade graphite zones have been discovered, which are usually connected with higher-grade rutile at the surface.

At a rutile grade of 1.01%, the underlined cut-off of 0.70% yields 1.8b tonnes, triple the previous MRE, with high-quality components yielding over 352m tonnes at a rutile grade of 1.44% at a 1.20% cut-off. At the global 0.7% cut-off, the total recoverable rutile equivalent grade for the MRE is 1.64% RutEq.

Sovereign’s Managing Director Dr Julian Stephens commented, “It is a really remarkable achievement by our team to have made the largest natural rutile discovery ever in just two years since initial identification. The JORC MRE of this scale and grade is clearly highly strategic, Tier 1 and of global significance in a market where natural rutile is in extreme supply deficit.”

“The step-change in scale will now allow us to examine potentially higher-grade throughput, increased production levels and a longer mine life in the upcoming scoping study update.”

“The company is targeting a large-scale, low carbon-footprint and environmentally sustainable natural rutile and graphite operation which will also positively impact the environmental footprint of titanium pigment and other industries, and provide a significant contribution to the economy of Malawi.”

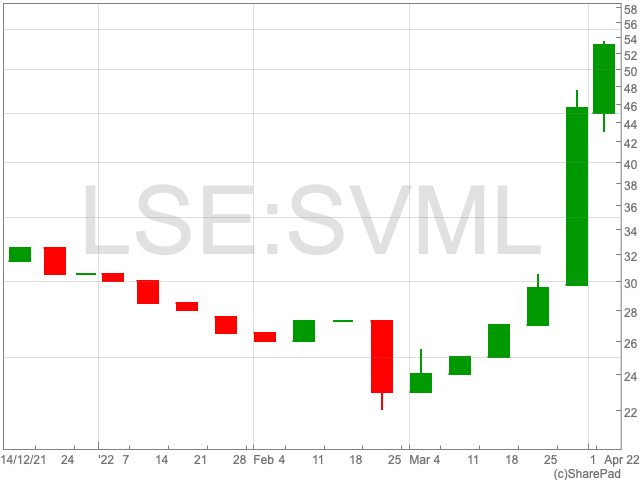

Sovereign Metal’s shares soared 16.5% to 53p after the company announced finding the largest rutile deposit ever discovered in Kasaiya, the group’s flagship project in Malawi.